What Is Cathode Ray Oscillator?

Why You Should Calibrate Your Cathode Ray Oscilloscope

A cathode-ray oscilloscope, or CRO, is a device that measures voltage and current flow in circuits. As electricity flows through the circuit, the device creates an image of the voltage as well as several other important measurements. The image may appear similar to that created by an oscilloscope, which creates an image of sound waves produced by music or machinery; however, the CRO does not show sound waves but rather a voltage and other information about what is happening in the circuit being tested.

A cathode-ray oscilloscope, or CRO, is an essential tool in almost any electronics lab, from manufacturing to repair to electronics design and development. However, many people fail to perform an essential step of owning a CRO: calibration. The following discussion covers some of the reasons why you should calibrate your CRO and how to go about it. After reading this article, you’ll have an idea about the importance of the process and how it can save you time and money in your electronics projects.

Today, we will be looking at why it’s important to calibrate your Cathode Ray Oscilloscope (CRO). Calibration can be an intimidating topic, and it’s not something that many novice engineers or even experienced engineers think about regularly, but it’s an important process if you want your measurements to be accurate.

What Is Cathode Ray Oscillator?

The cathode ray oscillator (CRO) is an electronic test instrument used to display and analyze electronic signals. Its use is particularly widespread in science and electronics laboratories, where it forms a mainstay of high-end equipment used by research engineers, who know its full name as an oscilloscope. This type of display device typically measures time, frequency or amplitude. The CRO works on simple physics principles: an electron beam strikes a phosphor-coated screen and excites it to light up at different intensities depending on its brightness. This happens because electrons strike phosphors with low kinetic energy – emitting dim light – while those with higher energy levels strike phosphors in quick succession to emit brighter light at once.

The most common cathode ray oscillators have two control knobs: one for horizontal position and another for vertical position. Rotating these knobs moves a marker along a scale on the CRO’s face to indicate specific points in time, frequency or amplitude readings. However, some models have more controls that allow users to move additional markers along with multiple scales simultaneously. For example, you can move one marker along a voltage scale while another follows your signal’s shape over time as you do so, lines that represent voltage vs.

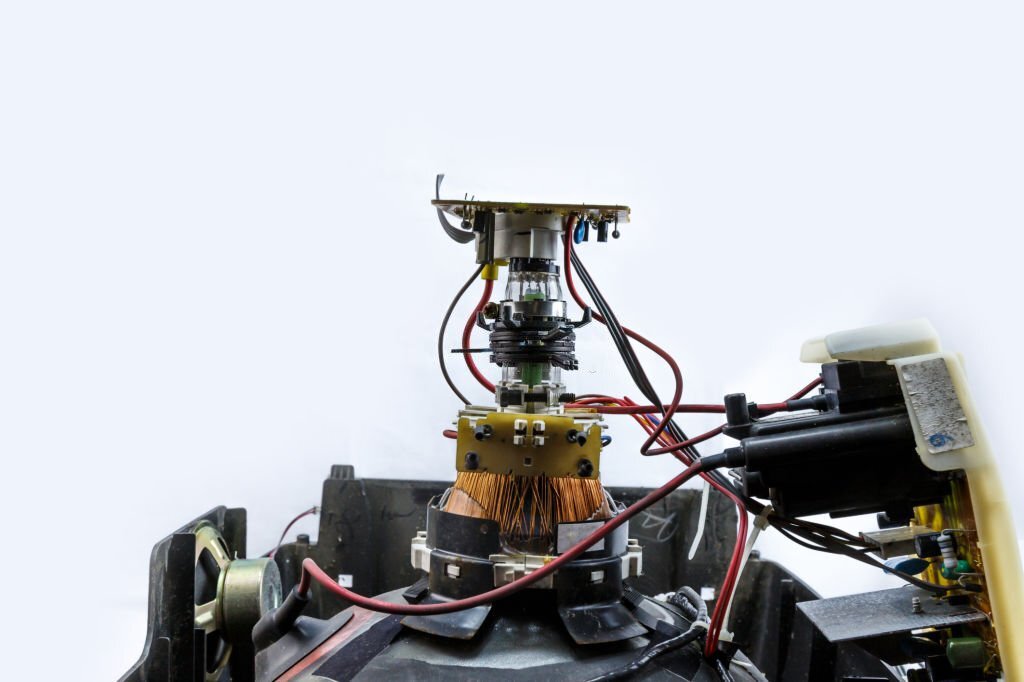

Construction of Cathode Ray Oscilloscope

The main parts of a cathode ray oscilloscope are an electron gun, which generates and projects a beam of electrons, a focusing lens to enlarge and direct the path of these electrons, and deflecting coils that allow precise control over horizontal and vertical deflection positions (X-Y coordinates), and electronic amplifiers for monitoring. However, unlike with most electronic equipment, its test probes are not part of its casing but instead are connected directly to it through a coaxial cable. The cathode ray oscilloscope is an analogue device; it receives an input voltage from its inputs and then displays that waveform as current in various locations on the screen relative to the X-Y axis.

Introduction to cathode-ray oscilloscopes

A cathode-ray oscilloscope (CRO) is a type of electronic test instrument that allows the observation of waveforms in both analogue and digital circuits. CROs are used in laboratories, design and manufacturing facilities to measure, display and analyze waveforms from a circuit under test. The CRO was first developed in 1897 by physicist William Crookes who described it as the glory hole among instruments because it could display an instantaneous electric current. The cathode ray tube (CRT) was invented earlier by Karl Ferdinand Braun in 1876, but its use for displaying waveforms did not become practical until 1897, when Lee De Forest applied new amplification technology to produce oscillations. Today, CROs have largely been replaced by modern electronic instruments such as logic analyzers and digital storage oscilloscopes. However, some applications still require their use due to certain advantages they offer over newer technologies. For example, unlike logic analyzers which can only capture high-level signals directly from ICs or other devices, CROs can also capture low-level signals that may be present at points on a printed circuit board or within components themselves. This makes them useful for troubleshooting circuits containing discrete components or those requiring measurements at low voltages or currents where other types of equipment may be unable to detect anything useful.

What Is Oscilloscope Calibration?

The cathode ray oscilloscope is a very useful instrument that can be used to view varying electrical signals in order to monitor and analyze an AC circuit. It can also be used to test some types of DC circuits. However, one big problem with oscilloscopes is that they are inherently unreliable devices. To ensure that your oscilloscope readings are accurate and reliable, you should calibrate it on a regular basis (at least once per month). One of the things to put into account is that there are different types of oscilloscopes available on today’s market (digital, analogue and digital storage), each with its own unique calibration procedure. Before getting started, you need to determine what type of scope you have, as well as how often you plan on using it. This will help you decide when and how often you should perform a calibration.

Working on Cathode Ray Oscilloscope

A cathode-ray oscilloscope is an electronic measuring instrument that produces a CRT display by scanning a focused electron beam across selected parts of an electronic circuit and measuring voltage, current or dissipation at discrete points in the circuit. The path of the electron beam is called a trace. Typically only one trace is visible onscreen at any time; traces are not stacked vertically. A CRO may use either analogue or digital techniques for measurement and display.

How Often Should I Perform Oscilloscope Calibration?

It’s recommended to have your oscilloscope calibrated once every six months, but most applications call for at least a quarterly calibration. Are you working in a heavily regulated environment? Like aerospace or healthcare, you may even be required to calibrate every month. By purchasing an oscilloscope that can store calibration values with each snapshot (like Tektronix Digital Storage Oscilloscopes), you can more easily stay compliant with regulations and still capture data as needed. To learn more about storing calibration values and how often to calibrate your scope, check out our latest whitepaper.

What Is An Accurate Measurement Without The Need For Equipment Adjustments?

Before you can get an accurate measurement from your equipment, you’ll need to make sure that it’s set up correctly. To get this, there are three measurements that should be taken into account: distance, time and frequency. Measuring these will ensure that whatever your equipment is measuring falls within a range of accuracy. If it doesn’t, it could mean big problems down the line in terms of productivity or quality control—or both! In order to take these measurements with confidence, you’ll need to properly calibrate your equipment when you don’t have to worry about making changes at all and can focus on doing what needs to be done with full confidence and accuracy.

How Do I Maintain My CRO’s Probe Tip?

As a highly sensitive test instrument, any damage to your CRO probe tip or imperfections in its surface will directly affect its performance. In fact, if there is a crack or chip in the tip of your CRO probe, it may not work at all. With regular calibration and maintenance checks to ensure your CRO probe is performing optimally and in good condition, you can avoid issues that could otherwise cause costly downtime for your equipment. But how do you know when to perform these maintenance checks? There are two important things to keep an eye out for frequency and resistance. The higher your frequency and lower your resistance, the more often you should check on your probe’s condition. If either number gets too high, it means that either something has happened to impact its performance or there is some kind of defect in its surface. Either way, you’ll want to replace it before using it again so as not to risk damaging your equipment with inaccurate readings.